The global electrolyser market size is on the cusp of significant growth, having reached a value of approximately USD 461.85 million in 2023. This promising sector is poised for further expansion, with projections indicating a compound annual growth rate (CAGR) of 27.30% during the forecast period of 2024-2032. By the end of this decade, the market is expected to reach a value of around USD 4,054.68 million. This blog post will delve into various aspects of the electrolyser market, including product segmentation, capacity, applications, regional analysis, and competitive landscape.

Understanding the Electrolyser Market

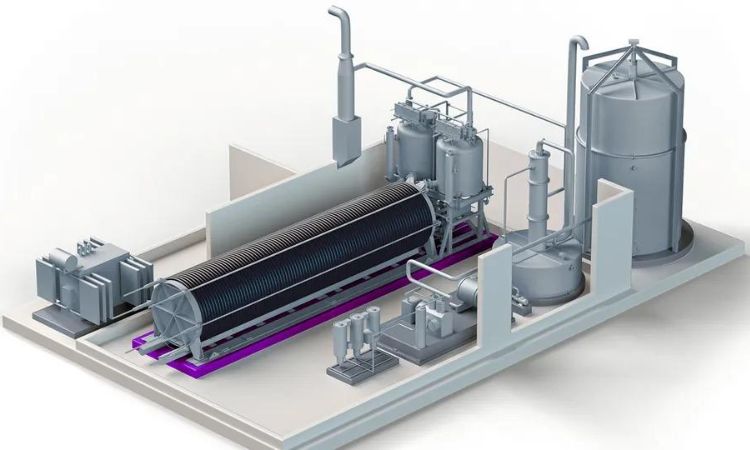

Electrolysers are devices that utilize electrical energy to drive chemical reactions, specifically the electrolysis of water to produce hydrogen. As the world shifts towards renewable energy sources, the demand for hydrogen as a clean fuel has surged, positioning electrolysers at the forefront of this transition. They play a pivotal role in reducing greenhouse gas emissions, making them essential for achieving global sustainability goals.

Market Size and Share

The global electrolyser market is experiencing rapid growth, driven by a combination of technological advancements, increasing investments in renewable energy, and supportive government policies. The rise in hydrogen production from renewable sources is a major catalyst for this expansion. As industries and governments aim to decarbonize their operations, the demand for efficient and cost-effective electrolysis solutions continues to rise.

The electrolyser market has been buoyed by factors such as rising energy costs, environmental regulations, and the global push for energy independence. This creates a favorable backdrop for manufacturers and investors alike.

Product Segmentation

The electrolyser market can be categorized into three main types based on the technology used:

Alkaline Electrolyser

Alkaline electrolysers are one of the oldest and most established technologies in the hydrogen production space. They utilize an alkaline electrolyte, typically potassium hydroxide, to conduct electricity. Advantages of alkaline electrolysers include their relatively low cost and high efficiency in large-scale applications. However, they are less suited for rapid load changes and require regular maintenance. Despite these limitations, they hold a significant share of the market and are projected to continue growing, particularly in industrial applications.

Solid Oxide Electrolyser

Solid oxide electrolysers (SOEs) operate at high temperatures and use a solid ceramic electrolyte. Their ability to achieve higher efficiencies makes them an attractive option for producing hydrogen from both water and carbon dioxide. SOEs can also utilize waste heat from industrial processes, enhancing overall energy efficiency. The market for solid oxide electrolysers is expected to expand, especially as industries seek innovative ways to integrate hydrogen production with existing processes.

PEM Electrolyser

Proton exchange membrane (PEM) electrolysers represent a cutting-edge technology that has gained traction due to their high efficiency and flexibility in operation. PEM systems can quickly respond to fluctuating energy inputs, making them ideal for applications involving intermittent renewable energy sources, such as solar and wind. As more industries adopt PEM technology, this segment is anticipated to see substantial growth, especially in transportation and power generation sectors.

Capacity Segmentation

The market can also be segmented by capacity, with three main categories:

Less than 500 kW

Electrolysers in this category are often used for small-scale hydrogen production, typically in decentralized applications. These systems are particularly valuable for residential and commercial users looking to integrate hydrogen solutions into their energy systems.

500 kW – 2 MW

This segment represents a significant portion of the market, serving medium-scale applications. Industries looking to incorporate hydrogen into their operations often rely on electrolysers in this capacity range. The growth in this segment is driven by increasing industrial demand for clean hydrogen solutions.

Above 2 MW

Large-scale electrolysers are crucial for meeting the growing hydrogen demand in sectors such as transportation and power generation. These systems can produce hydrogen in significant quantities, making them suitable for large industrial operations. The market for electrolysers above 2 MW is expected to flourish as industries seek more efficient ways to produce and utilize hydrogen.

Application Segmentation

Electrolysers serve various applications, each with unique market dynamics:

Transportation

Hydrogen fuel cell vehicles are becoming more popular as a clean transportation option. Electrolysers are vital for producing green hydrogen, which powers these vehicles, aligning with global decarbonization efforts.

Power Generation

Electrolysers play an essential role in integrating renewable energy sources into the grid. They can convert excess electricity from solar and wind into hydrogen, which can be stored and used to generate power when demand is high.

Industry Feedstock

Many industries use hydrogen as a feedstock for chemical processes. As industries strive to reduce carbon footprints, the need for green hydrogen produced via electrolysis is growing rapidly.

Industry Energy

Electrolysers also provide energy solutions for energy-intensive industries, enabling them to transition towards more sustainable practices. This application is expected to gain momentum as industries seek to align with environmental regulations.

Others

Emerging applications, such as hydrogen production for heating and power backup systems, are beginning to shape the market landscape. These niche markets offer additional growth opportunities for electrolyser manufacturers.

Regional Analysis

The global electrolyser market exhibits significant regional variations. North America and Europe are currently leading in market share, driven by stringent environmental regulations and substantial investments in renewable energy. The Asia-Pacific region is emerging as a significant player due to rapidly industrializing economies and increasing government initiatives to promote hydrogen production.

North America

In North America, countries like the United States and Canada are investing heavily in hydrogen infrastructure, bolstered by favorable policies and incentives. Major companies are also ramping up research and development efforts to enhance electrolyser technology.

Europe

Europe is at the forefront of the hydrogen economy, with countries such as Germany and the Netherlands implementing ambitious hydrogen strategies. The European Union’s Green Deal is pushing for increased use of renewable hydrogen, further stimulating market growth.

Asia-Pacific

Countries like Japan and South Korea are making substantial investments in hydrogen production technologies, positioning themselves as leaders in the electrolyser market. Emerging economies in the region are also beginning to adopt hydrogen solutions as part of their energy strategies.

Competitive Landscape

The electrolyser market is competitive, with several key players dominating the landscape. Companies such as Siemens, Nel ASA, and ITM Power are investing heavily in research and development to innovate and capture a larger market share. Recent mergers and partnerships have further intensified competition, leading to advancements in technology and production efficiency.

Future Trends and Forecast (2024-2032)

As we look towards 2032, the electrolyser market is set to undergo transformative changes. Technological advancements will continue to improve efficiency and reduce costs, making hydrogen production more accessible. Additionally, regulatory support and global commitments to reducing carbon emissions will drive the adoption of electrolysers across various sectors.