Inventory optimization is critical for maintaining efficiency, reducing costs, and enhancing customer satisfaction in any business. By implementing best practices, businesses can streamline their processes and improve profitability. This guide explores essential strategies to ensure effective inventory management.

· Introduction to Inventory Optimization

Inventory optimization is about maintaining the right balance between supply and demand. It helps businesses avoid overstocking and stockouts, improving cash flow and operational efficiency. A well-optimized inventory system ensures that businesses can meet customer demand without incurring unnecessary costs.

· Accurate Demand Forecasting

One of the first steps toward optimizing inventory is accurate demand forecasting. Understanding consumer trends and seasonal fluctuations is essential. Businesses should use historical data to predict future demand patterns. This enables timely stock replenishment and avoids overstocking, which can lead to wasted resources.

· Implementing RFID Technology

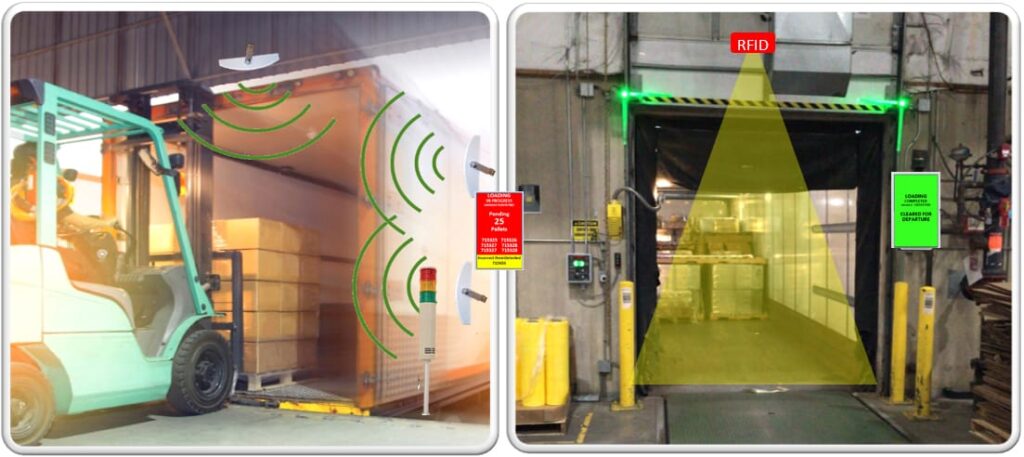

Using advanced technology like RFID technology for inventory management helps businesses keep track of stock levels with precision. RFID systems can automate the inventory tracking process, reducing human error and ensuring real-time visibility of stock. With RFID, businesses can respond quickly to changes in demand, improving overall efficiency.

· Regular Inventory Audits

Regular audits are crucial for identifying discrepancies between actual stock levels and recorded data. Physical inventory checks should be conducted periodically to ensure accuracy. Audits help businesses spot inconsistencies that could lead to loss of revenue or supply chain inefficiencies. This practice also enhances decision-making by providing accurate insights.

· Balancing Inventory Costs

Balancing the cost of holding inventory and potential stockouts is a key aspect of optimization. Businesses should evaluate the carrying cost, including storage and insurance, against the risk of stockouts, which can lead to lost sales. Optimizing reorder points based on these factors ensures that inventory levels are always in line with demand.

· RFID Solutions for Retail

Retailers benefit greatly from RFID solutions for retail, which offer enhanced inventory accuracy and real-time tracking. RFID allows seamless stock updates, reducing the likelihood of out-of-stock situations or overstocking. Implementing RFID technology can improve the efficiency of inventory management, allowing retailers to focus on customer satisfaction.

· Supplier Relationship Management

Building strong relationships with suppliers is essential for effective inventory management. Timely communication and regular collaboration with suppliers can lead to more efficient order processing. Establishing clear terms for delivery schedules and lead times ensures that inventory levels are maintained without excessive delays or overstock.

· Continuous Improvement and Adaptation

Inventory optimization is not a one-time task. Businesses should continually review and adjust their inventory strategies based on market conditions and consumer trends. By embracing new technologies and refining processes, businesses can ensure their inventory remains efficient and aligned with changing demands.

Conclusion

Optimizing inventory is essential for maintaining operational efficiency, reducing costs, and improving customer satisfaction. By employing demand forecasting, utilizing advanced technologies like RFID, conducting regular audits, and managing supplier relationships, businesses can achieve a well-balanced and efficient inventory system.